Lead Sheet Has Been Used Throughout History for Waterproofing and Coating of Circular Structures. With the Development of Science, the X-Ray Tube was Discovered by Wilhelm C. Röntgen in 1894. With the introduction of X-ray devices, the rooms where the X-ray devices were installed began to be armored with lead sheets in order to prevent destructive damage from environmental and biological factors.

The reasons why lead sheets are used are that they have a high density, can protect themselves for many years without deterioration, and have high radiation resistance.

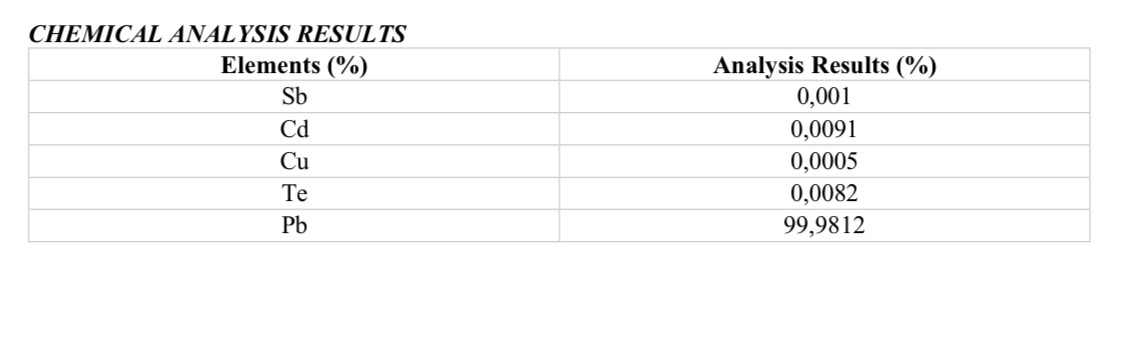

Lead Plate; It is used as a shield in radiation shielding of X-ray rooms. High Purity Leads Provide Better Radiation Shielding Compared to Standard Leads. Lead Purity Should Be Checked with Spectral Analyzes Before and After Production. In our country, NDK has the authority to carry out post-armoring checks. The use of lead in accordance with the standards given by NDK will ensure that your project receives a problem-free license.

Lead Sheet; It is produced by pouring pure lead ingots into molds at 450 C° after the melting process and rolling them (rolling press). After the Rolling Process, the Leads are Shaped into Lead Sheets in the Desired Dimensions by Guillotine Cutting Process. During Production, Samples Are Taken From Induction Furnaces At Each Crucible Casting And The Purity Degree Is Checked.

Lead Sheets are used in many areas, from exterior cladding in buildings to cable manufacturing. The Lead Sheets We Produce are Produced in High Purity and at the Highest Standards in Compliance with Radiation Insulation and Safety Regulations.

Lead is accepted in international standards as the most ideal armoring material to be used as an armoring material against radiation. Since a large portion of our production is exported, our products are produced in European Standards (CE). Standard checks are carried out annually and our certificates are renewed every year.

We have 3 different companies in the field of radiation safety, and we provide services in many countries with our expert team in the field of radiation protection, including product manufacturing and domestic and international project consultancy.

”As the Purity Rate Increases, Lead Plate Provides Radiation Resistance Many Times More Than Standard Lead Sheets. ”

Lead Sheet Weight Chart

You can calculate the lead weight you need with the lead sheet weight and size table.

| Lead Sheets Thickness | Lead Sheet Dimensions | Lead Sheet Weight |

| 0.5 MM | 100CMX200CM / 50CMX200CM | 11,37 KG / 5,685 KG |

| 0.8 MM | 100CMX200CM / 50CMX200CM | 18,19 KG / 9,095 KG |

| 1 MM | 100CMX200CM / 50CMX200CM | 22,74 KG / 11,37 KG |

| 1.2 MM | 100CMX200CM / 50CMX200CM | 27,28 KG / 13,64 KG |

| 1.5 MM | 100CMX200CM / 50CMX200CM | 34,11 KG / 17,055 KG |

| 1.8 MM | 100CMX200CM / 50CMX200CM | 40,93 KG / 20,465 KG |

| 2 MM | 100CMX200CM / 50CMX200CM | 45,48 KG / 22,74 KG |

| 2.5 MM | 100CMX200CM / 50CMX200CM | 56,85 KG / 28,425 KG |

| 3 MM | 100CMX100CM / 50CMX200CM | 34,11 KG / 34,11 KG |

| 4 MM | 100CMX100CM / 50CMX200CM | 45,48 KG / 45,48 KG |

| 5 MM | 100CMX100CM / 50CMX200CM | 56,85 KG / 56,85 KG |

| 6 MM | 50CMX50CM | 17,05 KG |

| 7 MM | 50CMX50CM | 19,89 KG |

| 8 MM | 50CMX50CM | 22,74 KG |

| 9 MM | 50CMX50CM | 25,58 KG |

| 10 MM | 50CMX50CM | 28,42 KG |